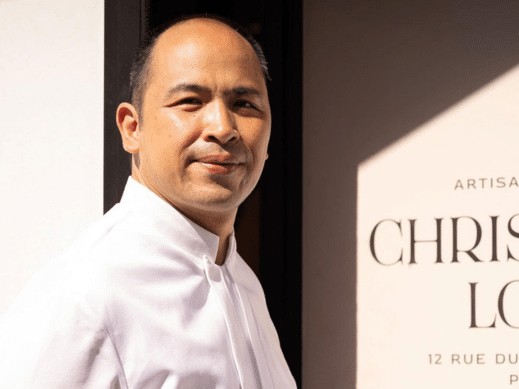

Exceptional craft,

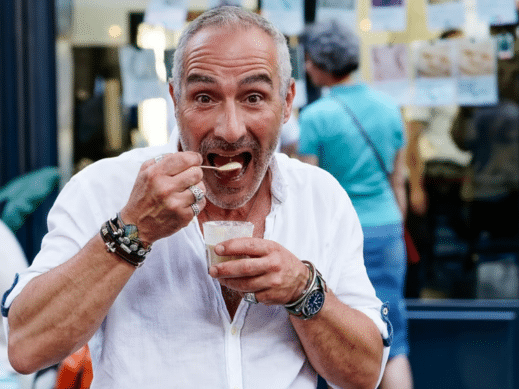

Exceptional flavour

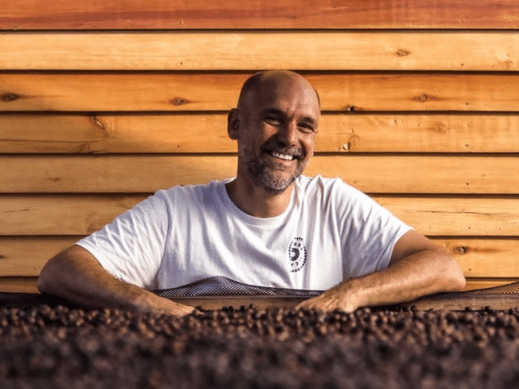

The flavour is unlike anything you’ve experienced. Because cacao has never been cultivated this way before.

SINGLE-VARIETY.

GRAFTED FOR FLAVOUR.

We are honoured to present our masterpiece to the culinary creators of the world, in anticipation of the extraordinary experiences we will create together.

We began our journey in Central America, over 18 years ago and are now distributing our chocolate couverture all around Europe.